The Role of Technology in Modern Industrial Facilities in Malaysia

- Simon Lim

- Nov 4, 2024

- 3 min read

In recent years, industrial facilities in Malaysia have undergone a significant transformation driven by the rapid advancement of technology. From automation to smart systems, modern industrial operations have embraced cutting-edge technologies to boost efficiency, safety, and sustainability. This shift is not only enhancing productivity but also positioning Malaysia as a competitive player in the global industrial sector.

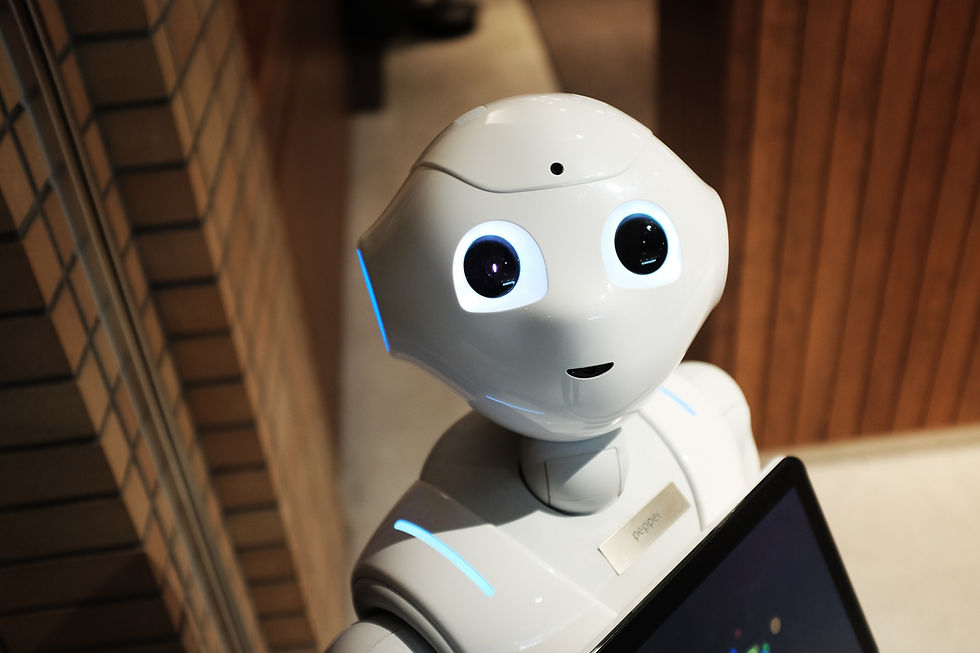

1. Automation and Robotics

Automation has become a key pillar in modern industrial facilities. In Malaysia, industries like manufacturing, electronics, and automotive are leveraging automation and robotics to streamline processes, reduce human error, and enhance output. Automated machinery can work around the clock, leading to increased production rates, while robotics are being used for repetitive and dangerous tasks, ensuring worker safety and precision.

Local manufacturers are increasingly integrating technologies such as robotic arms, conveyor systems, and automated quality control into their production lines. This reduces labor costs, improves product quality, and shortens production cycles.

2. Smart Factories and IoT Integration

The rise of the Internet of Things (IoT) has paved the way for smart factories, where interconnected devices communicate and optimize industrial processes in real-time. In Malaysia, smart factories are utilizing IoT technology to monitor equipment performance, track inventory, and improve predictive maintenance.

For example, sensors embedded in machines can collect data on temperature, pressure, and vibration, allowing operators to identify potential issues before they lead to breakdowns. This proactive approach minimizes downtime and helps industries maintain a smooth production flow. Furthermore, IoT systems enable better energy management, allowing factories to monitor energy consumption and optimize usage, contributing to reduced operational costs and a smaller carbon footprint.

3. Advanced Manufacturing with 3D Printing

3D printing, also known as additive manufacturing, is gaining momentum in Malaysia's industrial sector. This technology allows manufacturers to create complex parts and prototypes quickly and cost-effectively. With 3D printing, industries can experiment with new designs, reduce waste, and achieve faster time-to-market for innovative products.

Industries ranging from aerospace to medical devices are adopting 3D printing for prototyping and small-batch production. By embracing this technology, Malaysian manufacturers can customize products to meet specific client requirements while minimizing material usage and production time.

4. Sustainability and Energy Efficiency

As environmental concerns grow, many industrial facilities in Malaysia are investing in technologies that promote sustainability. Renewable energy sources, such as solar power, are being integrated into industrial plants, reducing reliance on fossil fuels. Additionally, energy-efficient equipment and smart energy management systems are helping factories minimize waste and lower their carbon emissions.

Malaysia's government has been actively supporting green initiatives through various incentives, encouraging industrial players to adopt energy-efficient practices. These efforts not only benefit the environment but also contribute to long-term cost savings for businesses.

5. Data Analytics and Artificial Intelligence

Data analytics and artificial intelligence (AI) are playing an increasingly important role in optimizing industrial processes. By analyzing large sets of data, AI-driven systems can predict trends, optimize supply chain management, and improve decision-making.

In Malaysian industrial facilities, AI is being used for demand forecasting, quality control, and process optimization. For instance, AI algorithms can identify patterns in production data and recommend adjustments to reduce defects and enhance product quality.

Additionally, data analytics helps industries make informed decisions about resource allocation, inventory management, and operational efficiency.

6. Enhanced Workplace Safety

Technology is also transforming workplace safety in industrial facilities. With the integration of advanced safety systems, such as automated fire suppression systems, surveillance cameras, and wearable safety devices, industrial plants can ensure the well-being of their workers. In Malaysia, industries are adopting real-time monitoring solutions that alert workers and supervisors to potential hazards, reducing the risk of accidents.

For instance, wearable devices can monitor workers' vital signs and detect signs of fatigue, enabling employers to take preventive measures before accidents occur. Additionally, AI-powered cameras can analyze real-time video feeds and detect unsafe behaviors or situations, further enhancing workplace safety.

7. The Road Ahead for Malaysian Industrial Facilities

The role of technology in Malaysia's industrial sector is poised to grow even further in the coming years. As industries continue to invest in digitalization, automation, and sustainability, Malaysia's industrial facilities will become more efficient, resilient, and competitive on the global stage.

The adoption of advanced technologies not only supports the country's ambition to be a leading industrial hub in Southeast Asia but also aligns with the nation's goals for sustainable development and Industry 4.0. By continuing to embrace technological innovation, Malaysia's industrial sector can expect to see improved productivity, reduced environmental impact, and a stronger global presence.

Conclusion

The integration of technology in modern industrial facilities is revolutionizing the way businesses operate in Malaysia. From automation and IoT to AI and sustainability initiatives, these advancements are driving efficiency, improving safety, and reducing operational costs. As Malaysia continues to embrace these technologies, its industrial sector will remain a key driver of economic growth, creating new opportunities for both local and international businesses

Simon Lim

+6016-448 9663

Comments